Business area

Provide customers with the most appropriate waterjet process solution.

BlastMax™

-

Features

Aqua-Dyne BlastMax ™ waterjet is widely used in industries such as industrial cleaning, surface treatment, petrochemical and hydraulic (pressurized) test, and concrete crushing.

- Small Footprint

- Complete range of packaging options

- Parts precision machined for easy fit : Easy assembly/disassembly

- Individual lightweight split manifolds : Serviceable by one person during routine maintenance

- Aircraft quality steel : Long life, 5x less maintenance

- Individual check valves and valve seat : Check valves and valve seat can be relapped and reused

- Quick and easy access of all filters replacement

- 180+ degree access to the pump : Easy access makes faster maintenance

- Plunger conversion kits : Ability to run multiple flows and pressures for one platform

-

Model

BlastMax™, S250 and S500 models with pressure, flow, pressure-flow, horsepower, driving, application, tool quantity information Model Pressure Flow rate Pressure-Flow rate HP Driving Application Tool nos S250 345~2,758Bar

5,000~40,000psi30~249lpm

8~66gpm2400bar~24.5~30 250 Diesel Electronics Ship hull and large storage tank 2-3 guns / 1 hydrocat 1400bar-64.26 Small tube bundle Hydraulic test 2~3 1000bar-83.16 Medium tank cleaning 700bar-124.74 Shipyard cleaning 350bar-249.48 Hydraulic excavation S500 345~1,379Bar

5,000~20,000psi170~563lpm

45~149gpm1400bar-170.10 500 Diesel High pressure crushing Auto 1000bar-192.78 Large tank cleaning 6 or Auto 700bar-283.50 Large boiler cleaning 8 or Auto 350bar-563.22 Rubber paint cleaning, Maintenance 12 or Auto -

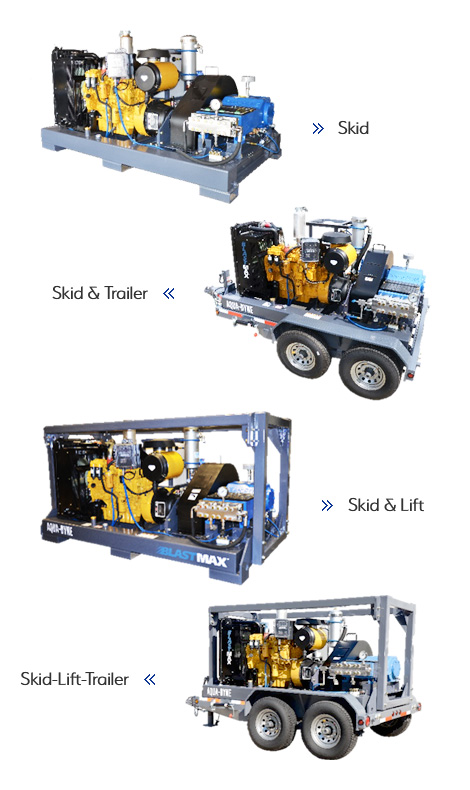

Packaging

Bare Shaft

Skid

Enclosure

Trailer

-

Hydraulic Blasting

Hydraulic blasting is applied to remove foreign debris and residues within the pressure range of 700 ~ 1,330 bar.

Application

- Boiler tubes

- Heat exchanger

- Mixer

-

High pressure cleaning

High pressure cleaning is applied to operations such as drilling, crushing and stripping within the pressure range of 1,400 to 2,000 bar.

Application

- Tube drilling

- Concrete crushing

- Ship Stripping

- Paraffin and crude residue

- Heat exchanger high pressure cleaning

-

Tools & Accessories

The choice of cleaning tools and accessories depends on what the contents (chemical byproducts, coke or cement, etc.) are, the diameter and shape (straight / curved) of the pipe and tube, the inside or outside of the vessel / tank, The nozzle and tool are determined according to the following.

Tool system

- Lancing equipment: Remote operation cleaning of tube bundles and heat exchangers

- RHD: Up to 1500 'pipe cleaning, easy to work on common bending areas in piping systems, lightweight and portable for use in narrow or high working areas

- Dump Gun: An efficient multi-use solution that allows the operator to hold the dump gun connected to the hose in the form of high pressure water sprayed with a fixed nozzle

- Rotating gun: High-pressure water is injected by rotary nozzle, saving water in waiting for injection and reducing worker fatigue

- Mini scrubber: With hand-held cleaning tools, you can collect blast residue by vacuum

- Floor cleaner: 12-18 "cleaning head to clean the surface by dragging the attached body

If you have any further reuqest or question on TOPS waterjet solution & service;

Contact Us