Industrial Solutions

Provide customers with the most appropriate waterjet process solution.

Industrial Solutions>Process automation solutions

Process automation Solutions

With industrial base,

Tops provides waterjet solution according

to the material characteristics.

Total :

9

(1 / 1 Page)

-

답변

Ceramic Cutting

In order to save loading/unloading time of cutting soft material such as glass fiber, insulation, rubber, sound absorbing material, sponge, etc.,

In order to save loading/unloading time of cutting soft material such as glass fiber, insulation, rubber, sound absorbing material, sponge, etc.,

The other table is designed to unload the finished product and load new materials while machining from one table.

Depending on the features of the cutting material, there are a catcher tank moving type, a grid transportation type, a table rotation type table design, and those can be transported manually or automatically. -

답변

Insulation Cutting

It is a waterjet solution for cutting E-glass fiber for insulation used in incineration, sound absorption and thermal insulation in various facilities such as shipbuilding, petrochemical, refinery, plant, and power plant.

It is a waterjet solution for cutting E-glass fiber for insulation used in incineration, sound absorption and thermal insulation in various facilities such as shipbuilding, petrochemical, refinery, plant, and power plant.

It provides clean work environment without cutting chips & dust scattering by pure water cutting. -

답변

Plant 3D Dome Cutting

It is a dedicated waterjet solution for 3D dome work in the fields of pharmaceuticals, plants, etc., and supports processing of 3D shapes.

It is a dedicated waterjet solution for 3D dome work in the fields of pharmaceuticals, plants, etc., and supports processing of 3D shapes.

Compared with conventional plasma and other methods, it is safe, clean, burrless, and non-toxic, making efficient and productive work possible. -

답변

Soft Material Cutting

To save the loading/unloading time of cutting soft material such as glass fiber, insulation, rubber, sound absorbing material, sponge, etc.,, the table is rotated according to the automatic transfer radius through the table configuration of radius circulation type.

It is designed to enable three-step process of product loading - cutting - unloading. -

답변

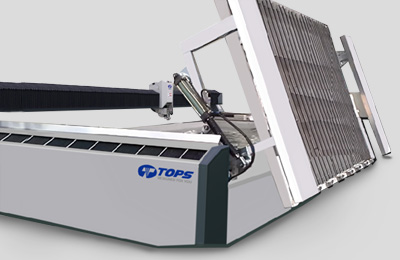

Architecture Glass Cutting

The glass cutting system is equipped with an automatic lifting device for loading/unloading the table and keep the lift angle as 6 °.

The glass cutting system is equipped with an automatic lifting device for loading/unloading the table and keep the lift angle as 6 °.

Separable grating construction makes easy seperation of gratings and easy to work with small parts. -

답변

High Pressure Deburring

Waterjet technology removes breakable burrs after screw-cutting, lapping, drilling, grinding operations without alteration of material characteristics (no heat affected zone), part dimensions and geometry. It also preserves straight angles and surface quality. Our deburring solutions prepare to high cleanliness levels, including inside parts that are difficult to reach. This unique process runs on any metal, from soft aluminum to hardest titanium.

Examples of parts using our waterjet deburring process include: diesel injection parts, hydraulic circuits parts, steering systems parts and more.

We have developed safe and high performance solutions to meet multiple geometry needs in mass production environments.

-

답변

Food Processing – Slitting & Portioning

Our ultrahigh-pressure technology offers practical solutions to many common food industry problems associated with traditional cutting methods. Product waste, production bottlenecks caused by equipment limitations and manual processing, downtime for blade maintenance, bacteria transfer and cross-contamination are reduced or eliminated.

Processors of fruit, vegetables, confectionaries, and meat products are all currently using Flow's waterjet "clean blade" waterjet separation technology to produce healthy, pathogen-free food products.

-

답변

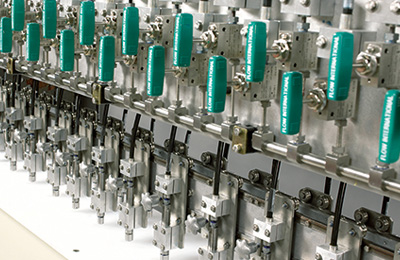

Slitters & Cross Cutters

Waterjet slitting systems are the fastest, most efficient way to cut paper products.

- Cut dust free, significantly improving work conditions, safety and product quality

- Eliminate rewinding – a slitter can be installed directly on the machine and the edge meets all requirements for converting operations

- Higher cutting speeds

- Redundant nozzles double the slitting time between "knife" changes

- Fast and easy positioning – manual or automatic

- Strong and clean cut edges. No blade to dull.

-

답변

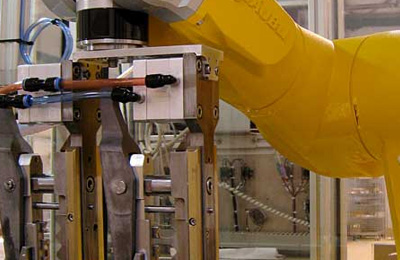

Multi-Axis Cutting for Production Requirements

6-axis robotic solutions for industrial abrasive and pure waterjet cutting applications.

5-Axis CNC gantry solutions for high accuracy requirements and/or intensive production.

24/7 industrial factory solutions, featuring for example: probing, abrasive management, waste management, water close-loop system, thermal management, process monitoring, remote access, part traceability, and more.

If you have any further reuqest or question on TOPS waterjet solution & service;

Contact Us